ERP software is a powerful tool that has revolutionized the manufacturing industry. However, this technology needs to be well understood and used properly to derive the benefits manufacturers expect for their investment. For many years our consultants have helped first-time users successfully implement ERP into their manufacturing businesses. During implementation, we make it a priority to ensure they understand the three manufacturing flows that describe the foundational manufacturing processes. Why? Because if a company fails to integrate ERP with their production processes, it is virtually impossible to maintain a successful, profitable manufacturing enterprise.

What is a Manufacturing Flow?

A manufacturing flow is a set of processes that guide equipment, people and work from start to finish. From our experience implementing ERP software, we have witnessed that a seamless integration between ERP and these three flows lays the foundation for efficient work processes and simplifies manufacturing throughout the business.

What are the Three Manufacturing Flows?

All manufacturing can be modeled on three distinct flows – Physical, Information and Money. Each flow is interactive and connected to the others, and all play equally important roles in connecting with a company’s ERP system.

-

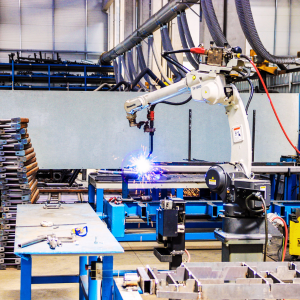

The Physical Flow is the movement of raw material, components and finished goods from one location to another. Inventory gets received, stored, moved, transformed, consumed and shipped. There are physical locations in the plant that store inventory, and physical modes of transportation to move the inventory.

-

The Information Flow (aka data) is a result of physical flow. Every time inventory moves or is transformed, it creates information that is essential to collect. Where is it now located on the shop floor? Has something changed its physical attributes? Any movement or transformation needs to be captured. Even if the inventory is just being stored, vital information is collected, such as shelf life or cost variances for the same part.

-

Like information, the Money Flow is a reactionary flow. Every time inventory is touched, moved, or transformed it creates a different value or cost. The inventory movement or transformation can be a direct or indirect cost that the company must account for. Even if inventory is just being stored, there are associated inventory carrying costs.

These are the three most important flows in any manufacturing plant because they drive every other flow that takes place. This is where ERP demonstrates its value by capturing and tying together all three flows. ERP provides the ability to monitor the movement of material flow and track the data in real time. It then displays the data for analysis and the translation of this data into financial information, providing an outcome where operations and finance are tied together in a prompt, accurate and clear way.

How Does Software Tie All Three Flows Together?

A fully integrated ERP system ties inventory, purchasing, shop floor operations, engineering, sales, quality and shipping with finance and accounting. ERP functions collect the data in real time through barcode/RFID and touch screen inputs, while paperless mobile applications can collect and send data from anywhere throughout the plant. The ERP system presents the data in clear, easily understood dashboards and graphics. When a company starts to see how these flows are presented in their operations, they begin to understand how ERP can help improve plant operations and financial performance.

Once manufacturers understand how a fully integrated ERP system works, they can begin designing the process step-by-step from start to finish, without delays or mistakes. This process of “achieving flow” will enable the shortest possible lead times. Productivity and quality will reach new heights. Floor space will be reduced at the design stage. The time required to do the work will be reduced by designing the work so it can be done in a continuous, uninterrupted sequence of steps, not by rushing or working faster. Slow and steady steps versus rushing ahead will facilitate a productive manufacturing flow.

Keeping Flows in Balance

Every time you move something it affects your dollars. Looking at the physical flow in person enables users to accurately describe and set up what it looks like in the ERP system. The better you can describe what you physically see, the better the ERP will work for you.

A good place to start is with receiving, because it’s easy to understand. The company takes physical acceptance of goods being received and replicates it in the ERP system. This tells the computer the items have been received, creating a physical transaction. Users can now find the physical receipt in the computer, because they can tell the computer where it is. They also know the associated costs because the receipt is tied to a purchase order.

By telling the computer to put the received item(s) in a specific bin, ERP users know the physical movement and the information while the money is identified on the receipt. If, for example, the money goes up one dollar due to physical movement, all three flows are in balance and make sense. The company received it, moved it, has it, and owns it. From the accounting side, physical movement has increased the inventory value by $1.

Any time a part is moved it changes the value. Taking something physically out of inventory for a specific job provides another example. The computer needs to reflect what was removed from inventory and put it on the work order. When the material becomes part of the finished goods, both the labor and material need to be added to the transaction. The material was moved from A to B in the ERP system, signifying that the financial transaction balances out as every flow should.

Putting descriptions of physical movement into the ERP system is vital. If the data isn’t entered into the ERP system, you may have to walk out onto the shop floor, try to find it, and hope it’s where it’s supposed to be. If not, you lose time and money. When data is entered promptly and correctly, every transaction can be described in the three manufacturing flows, making it easy to know where things are.

Always Tell the Truth

Every new ERP user needs to learn one critical aspect of ERP software from the very beginning: ERP is only as good as the data you put into it. In terms of manufacturing flow, you must track and reflect all physical movements so they can be accurately entered into the computer. If the data isn’t truthfully reflected in the system, you can’t trust it. If finance isn’t balanced it indicates errors occurring throughout the flow.

Every time you physically move something, it must be accurately reported on the shop floor. This introduces structure into what you do in the shop, so workers have accurate and real-time information to make informed decisions. When employees understand the importance of reflecting the movement in the ERP system, telling the truth becomes ingrained in how the company operates.

Inventory requires truthful reporting because it sits at the core of everything. It’s like a bank with a lot of money in it that always must be in balance. If your inventory numbers aren’t accurate, it can negatively impact almost every aspect of your production process. If the ERP screen indicates 100 parts in a location, there had better be 100 parts in that location on the shop floor. Many manufacturers barcode incoming inventory so they always know where the product is. It’s also a good idea to label the bins where the barcoded materials are stored. To avoid having too much or too little inventory, production location or bin number should always be identified in the ERP.

The Benefits of Manufacturing Flow and ERP

One of the most impactful benefits of these three manufacturing flows is reduced cycle times. The processes needed to build products are linked and balanced with the ERP system, enabling the product to move from process to process without interruptions. This produces many important benefits, including:

-

Shorter lead times

-

Faster delivery

-

Improved product quality

-

Less waste or rework

-

Reduced inventory levels

-

Less working capital

The three manufacturing flows – Physical, Information and Money – need to be done to ensure efficient, effective production processes. They require trained ERP users who know how to link the processes that build products with ERP’s remarkably accurate data tracking and displays.

Train your ERP users well. Use the real-time data in ERP to stay current with everything going on in your business. And tell the truth to your ERP system every time you enter information. Get your flows moving smoothly and accurately and it will lead to improved processes.